——Prestressed Tensioning Equipment——

Automated Prestressed Tensioning Steel Bars, satisfying skill demands, saving work volume and labor time.

Used for manned steel bar installation along fixing tracks. The front end of the machine is equipped with fixing screws. Fixing screws are embedded at the track finish end. Install steel bars from the track begin end to the finish end.

——Cleaning Equipment——

This cleaning machine can remove solid residues left on prestressed Floor Slabs during the production process, making them smooth, and maintaining track dryness and cleanliness, so that third-party steel bar installation can proceed.

This design saves time, manpower, and water usage, satisfying production efficiency improvements and business benefit growth.

—— Conveying and Stacking Device——

This conveying and stacking device adopts a humanized design, can be used independently, can be used to transport freshly formed prestressed Floor Slabs, smooth process, without causing time waste, without having to use crane elevators for products.

providing various types of solutions. Product length up to 12m, manufactured according to client needs, with extension up to 16m and weight of 20 tons. Its simple connecting system can process different products.

——Spray Printing Equipment——

This application procedure is equipped with high technology, and allows comprehensive computerization, thanks to its simple, thoughtful procedure, direct printing on finished products. marking products, aesthetic enhancement, greatly improving the manufacturer's image.

——Rail-type Cement Cutting Machine——

The Produced rail-type Cement cutting machine, From the simplest model to the newest series of automatic C50U type with cutting depth up to 500mm, equipped with various models of cutting tools to satisfy different client needs, low repair cost, with simple operation, and safety. This rail-type cutting machine rotates flexibly and can perform multi-angle cutting (such as horizontal and vertical). According to cutting depth, it can improve height by 30, 40, or 50cm, including a cooling water pump, and is equipped with electrical lines and flexible water pipes.

Its operation includes manual, semi-automatic, and automatic cutting cycles and position adjustment, achieving different degrees of automation in production.

——Multi-hole Floor Slab Arm Manufacturing Equipment——

Used in manufacturing multi-hole floor slab walls. This industry application corrects deformities, ridges, and subsidence, and can even produce manufactured panels, achieving 100% commercialization. This mixer adopts a unique hopper separating design. Through a crane, it will transport the well-mixed material to the floor slab forming machine for double-door feeding.

Its dual fratasado system can produce uniform surface finishes and high-quality floor slabs, and can facilitate third-party coloring, for example, spray printing.

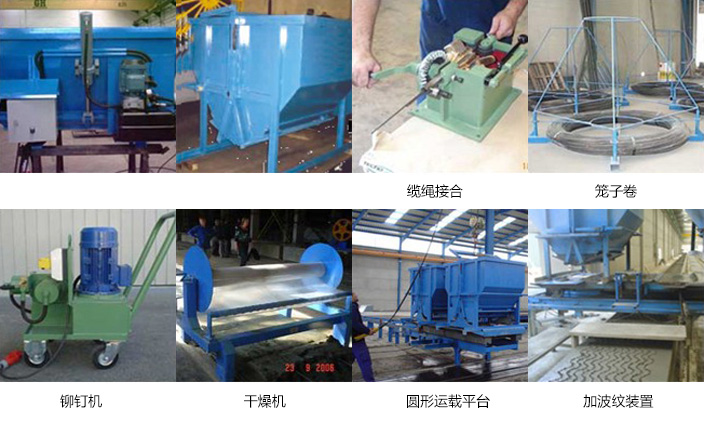

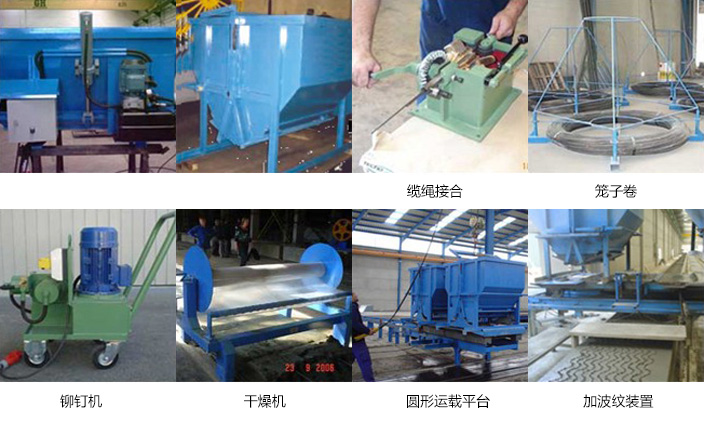

——Auxiliary Equipment——

——Stacking Device——

If you are interested in the above products, please fill out the form below, and the relevant personnel will contact you promptly.

0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com