Language

Language

——Features——

1. The new feed hopper can quickly and evenly feed materials into the mold for more uniform distribution. The new feeding trolley is equipped with wear-resistant and anti-leakage devices.

2. Adopts variable-frequency synchronous vibration; the vibration frequency can be adjusted for different process requirements, enabling low-frequency feeding and high-frequency forming, significantly improving product quality and output, effectively extending mold service life, and reducing cement consumption.

3. Equipped with an energy-saving vibrator to precisely control product height and reduce energy consumption.

4. Quick mold change system ensures rapid mold replacement; the adjustable vibration platform meets diverse production needs.

5. Multi-purpose machine; with mold changes it can produce various concrete products. Stable performance, high efficiency, and low maintenance.

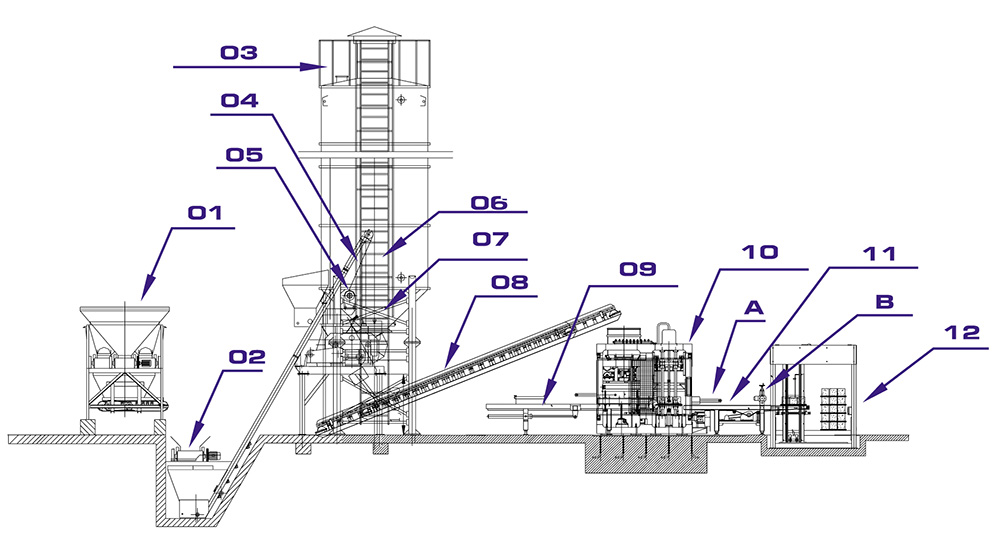

| Item | Model | Power |

| 01 3-bin Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 8M | 2.2KW |

| 03 Cement Silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7M | 7.5KW |

| 07 Forced Mixer | JS1000 | 51KW |

| 08 Mixing Material Conveyor | 8M | 2.2KW |

| 09 Pallet Feeder | For QT12-15 | 1.5KW |

| 10 QT12-15 Block Forming Machine | QT12-15 | 54.2KW |

| 11 Block Conveyor | For QT12-15 | 1.5KW |

| 12 Pallet Elevator | For QT12-15 | 3.7KW |

| A Face-material Device (Optional) | For QT12-15 | |

| B Brick Surface Cleaner (Optional) | For QT12-15 |

★The above configuration can be adjusted as needed. Optional items include: cement silo (50-100T), screw conveyor, batching station, side board lifter, loader, forklift, and air compressor.

Marketing Center

Tel:0595-22359222 22359333Overseas Sales

Tel:0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com