Language

Language

——Features——

1. One machine for multiple uses: by changing molds, it can produce various concrete block products. Compared with the QT6-15 model, output and production efficiency are significantly improved.

2. Pallet isolation device reduces pallet wear and effectively extends pallet service life.

3. Uses frequency-conversion synchronous vibration; vibration frequency can be adjusted according to process requirements, achieving low-frequency feeding and high-frequency forming. Changes in amplitude and frequency during conversion improve concrete flow and compaction.

4. We use only original imported hydraulic components to ensure reliability and accuracy. The control interface is easy to operate; users can switch between automatic and manual modes via the panel menu.

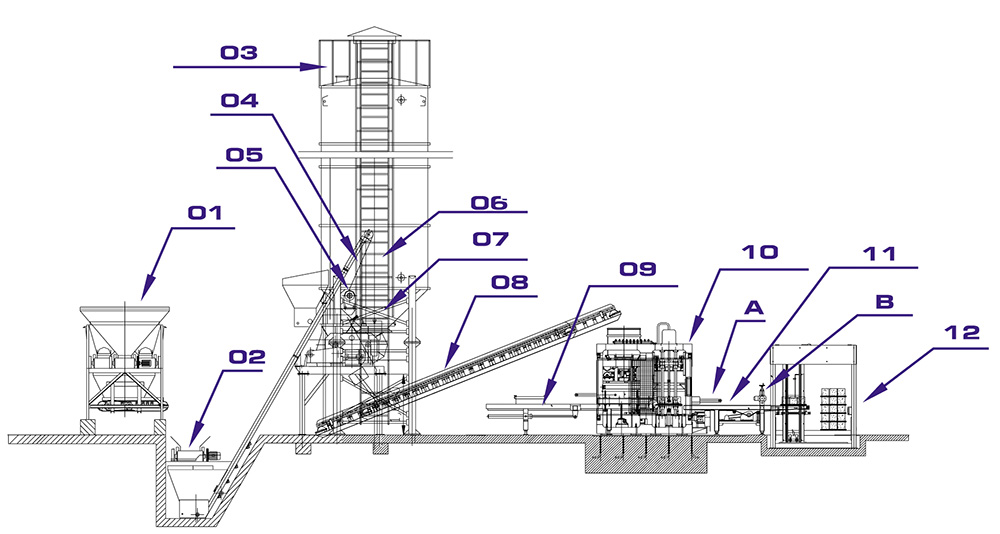

| Item | Model | Power |

| 01 3-bin Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 8M | 2.2KW |

| 03 Cement Silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7M | 7.5KW |

| 07 Forced Mixer | JS750 | 38.6KW |

| 08 Mixing Material Conveyor | 8M | 2.2KW |

| 09 Pallet Feeder | QT8-15Supporting | 1.5KW |

| 10 QT8-15 Block Forming Machine | QT8-15 | 46.2KW |

| 11 Block Conveyor | QT8-15Supporting | 1.5KW |

| 12 Pallet Elevator | QT8-15Supporting | 3.7KW |

| A Face-material Device (Optional) | QT8-15Supporting | |

| B Brick Surface Cleaner (Optional) | QT8-15Supporting |

★The above configuration can be adjusted as needed. Optional items include: cement silo (50–100T), screw conveyor, batching station, side pallet lifter, loader, forklift, air compressor.

Marketing Center

Tel:0595-22359222 22359333Overseas Sales

Tel:0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com