Language

Language

——Features——

1. The main machine uses steel pipe oil pipes,Not easy to break or leak oil。Oil tank equipped with oil pipe bracket,Convenient for equipment cleaning and maintenance。

2. Improved four-axis linked vibration system effectively and evenly transmits maximum vibration to the mold box, greatly improving product quality, while extending the service life of the mold.

3. Guide columns never need to be replaced, reducing maintenance costs. Fixed vibration platform, faster mold changing speed.

4. Photoelectric control of main machine material storage,Materials are delivered as needed,avoiding concrete premature liquefaction,Swinging feeding deviceMakes material distribution more uniform and stable。

5. This model has stable performance,Convenient maintenance,Can achieve automatic operation,Greatly reduces the labor intensity of operators。

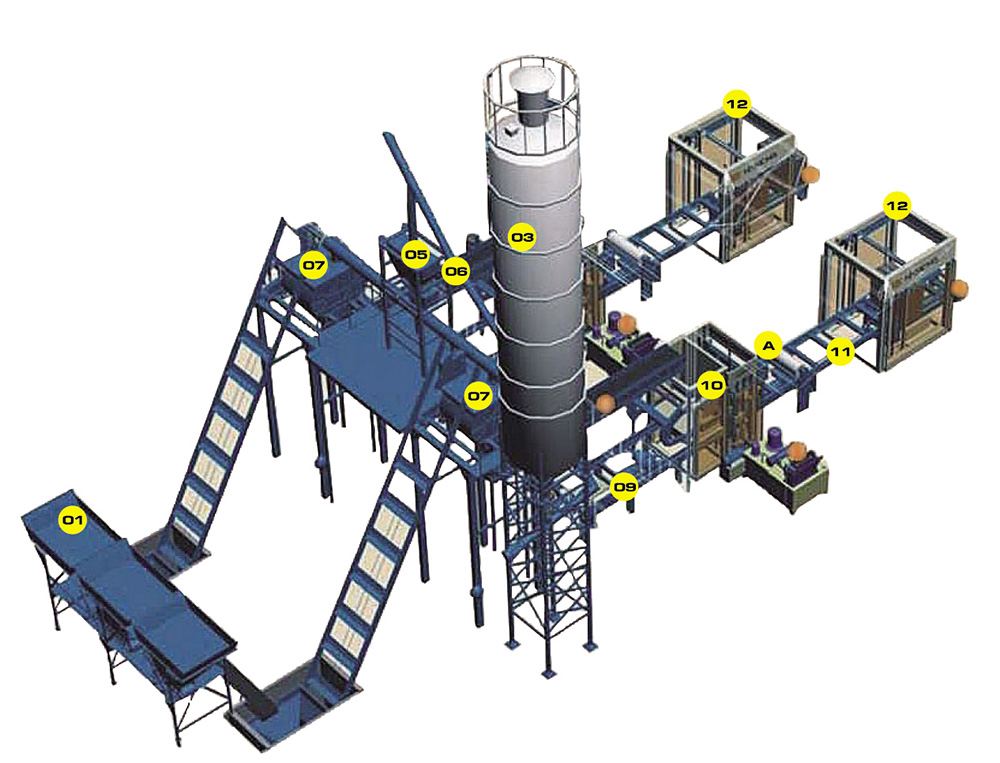

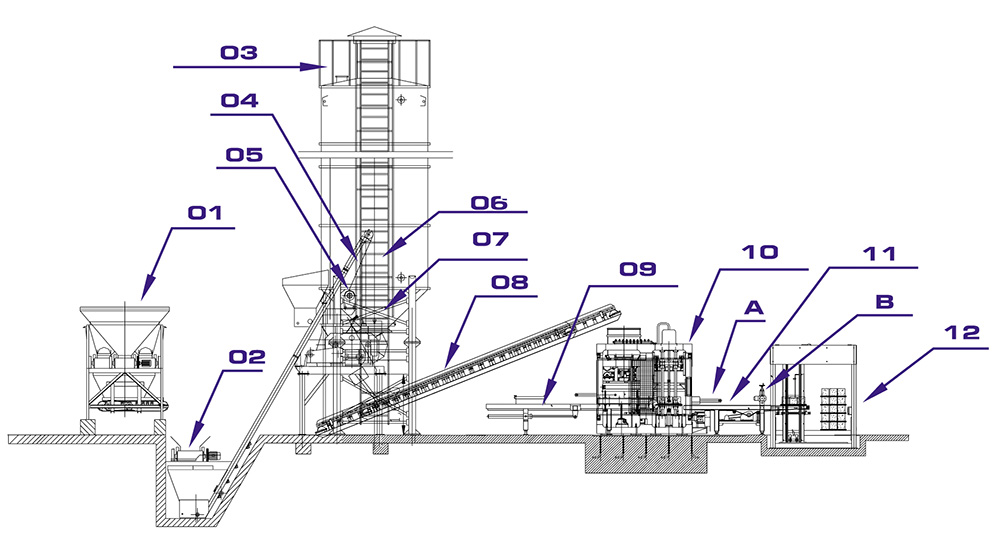

| Item | Model | Power |

| 01 3-bin Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 8M | 2.2KW |

| 03 Cement Silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7M | 7.5KW |

| 07 Forced Mixer | JS750 | 38.6KW |

| 08 Mixing Material Conveyor | 8M | 2.2KW |

| 09 Pallet Feeder | For QT10-15 | 1.5KW |

| 10 QT10-15 Block Forming Machine | QT10-15 | 48KW |

| 11 Block Conveyor | For QT10-15 | 1.5KW |

| 12 Pallet Elevator | For QT10-15 | 3.7KW |

| A Face-material Device (Optional) | For QT10-15 | |

| B Brick Surface Cleaner (Optional) | For QT10-15 |

★The above configuration can be adjusted as needed. Optional items include: cement silo (50-100T), screw conveyor, batching station, side board lifter, loader, forklift, air compressor.

Marketing Center

Tel:0595-22359222 22359333Overseas Sales

Tel:0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com