Language

Language

——Introduction——

Honcha focuses on tailoring production line configurations and provides solutions from simple to fully automatic lines based on different customer needs.

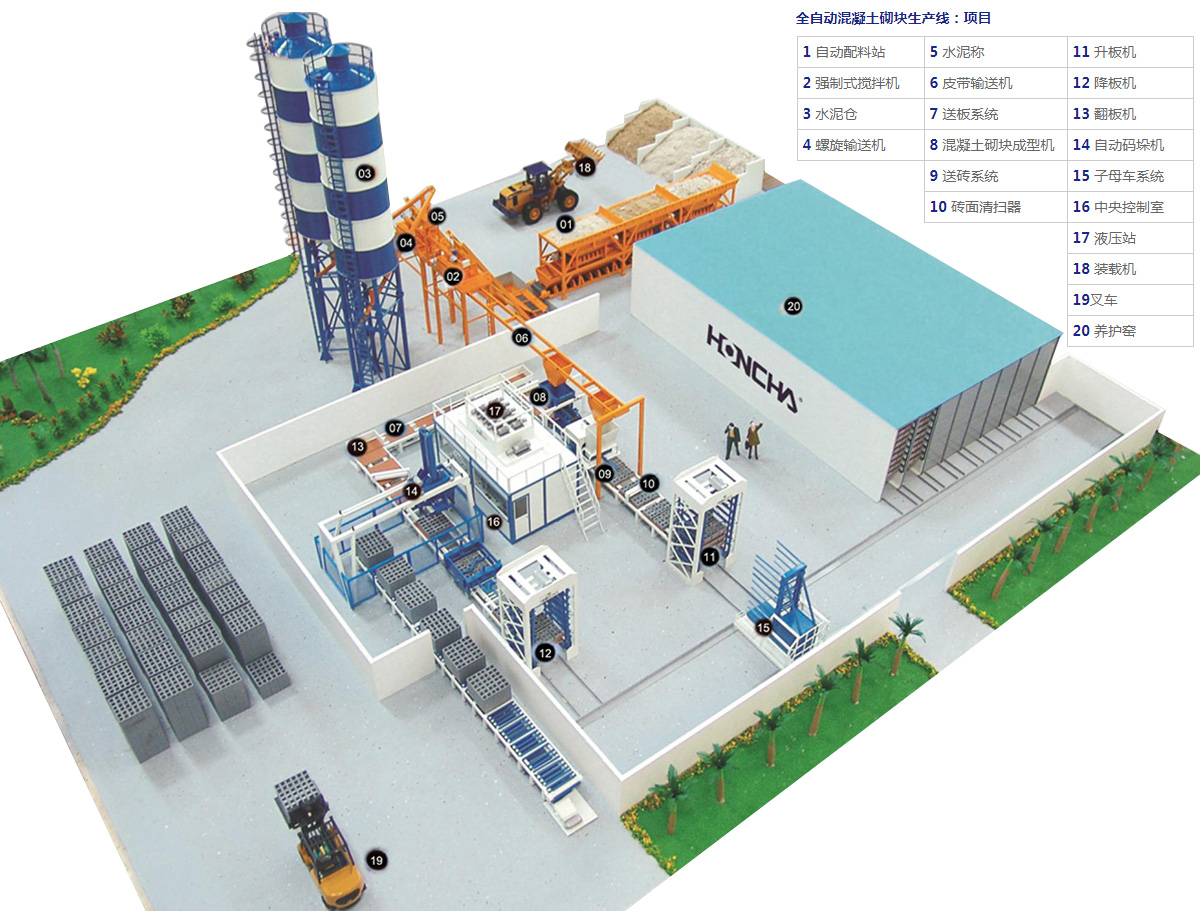

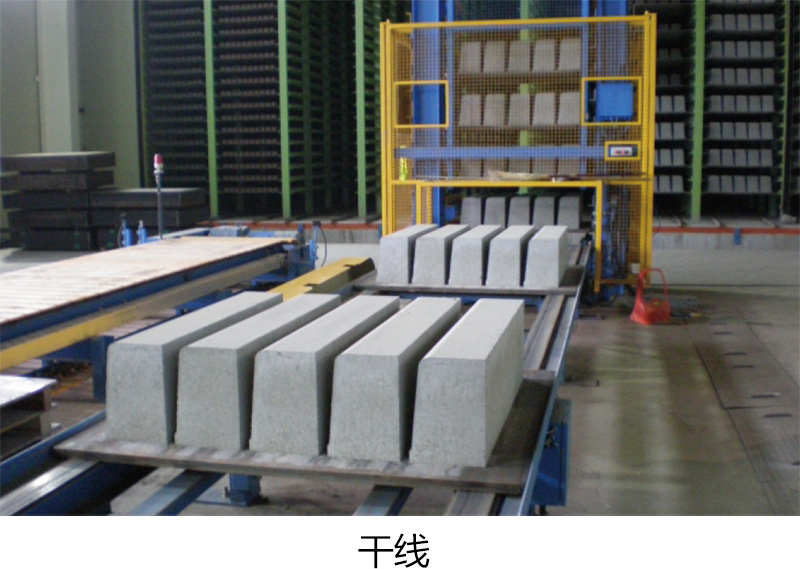

Fully automatic line process: The loader feeds different aggregates into the batching station for automatic proportioning and weighing, then mixes with cement from the cement silo. All materials are then sent to the mixer; after uniform mixing, a belt conveyor delivers the material to the block forming machine. After vibration and pressing, the products are cleaned by the brick surface sweeper and sent by the brick conveyor to the automatic plate lifter. Next, the parent-child cart transports all products on pallets to the curing kiln. After curing, the products are transported by the parent-child cart to the automatic plate lowering machine. The plate lowering machine sends the products to the brick conveyor and into the palletizing area for stacking, then a forklift moves them to the finished goods yard. The pallets are cleaned by the cleaner, flipped by the plate flipper, and returned to the forming machine for reuse.

——Components——

1. Batching and Mixing System

The batching and mixing system consists of cement silo (fly ash silo), automatic batching machine, conveyor, compulsory mixer or planetary mixer, cement scale, screw conveyor, and other equipment. It measures and mixes various raw materials according to preset ratios, and a conveyor delivers the mix to the forming machine.

● The automatic batching machine can meter two to four types of materials; choose the corresponding batching unit according to the forming equipment requirements.

● The cement silo, together with the cement scale and screw conveyor, makes cement feeding more accurate and reduces workplace pollution.

● The system is controlled by a PLC programmable controller; it is simple and reliable to operate and can be integrated into a centralized control system.

● The optional humidity sensing system measures the moisture content of various raw materials and controls the water addition ratio to ensure product quality.

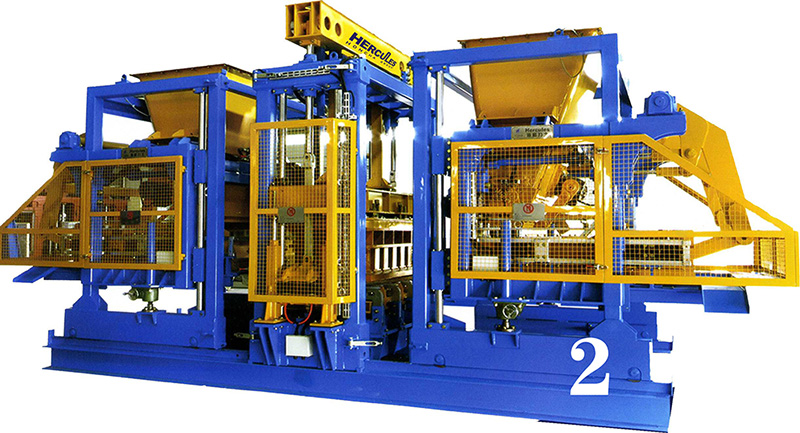

2. Block Forming Machine

The forming machine is controlled by computer/PLC with hydraulic drive and vibration pressing. With mold changes it can produce various concrete products; one machine with multiple uses, stable performance, high efficiency, and low maintenance rate. It supports real-time monitoring, fault alerts, HMI, and remote control.

Models available for the fully automatic line: Hercules 12, Hercules 15, Hercules 18.

3. Plate Lifter

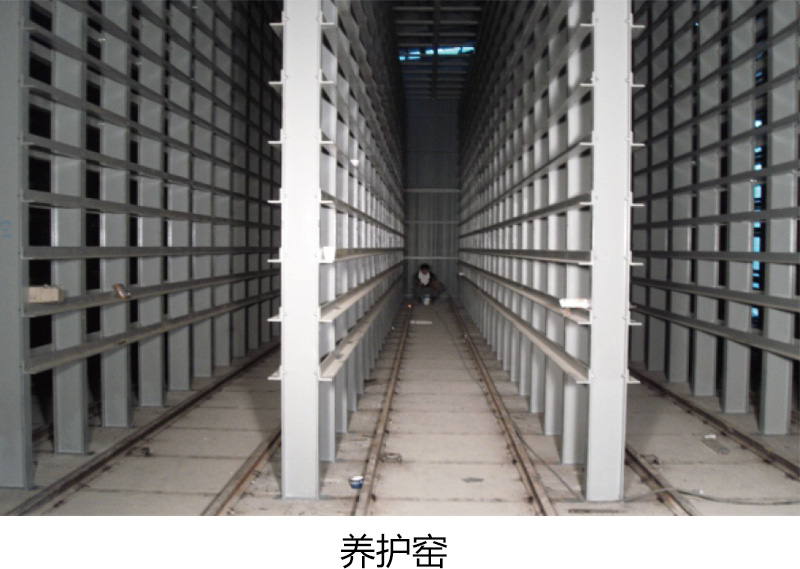

After being cleaned by the brick surface sweeper, the products are conveyed to the plate lifter. The plate lifter is part of the fully automatic curing system; it layers and lifts the products to a defined height to work with the parent-child cart.

4. Parent-Child Cart

Composed of a child cart and a mother cart operating on rails, traveling between the lifting/lowering machines and the curing kiln to transport freshly formed and cured products.

5. Plate Lowering Machine

The plate lowering machine sends cured products to the brick conveyor, then into the palletizing area for stacking. Pallets are returned to the forming machine via the return system for reuse.

6. Automatic Palletizing System

The palletizing system grips products from pallets and cross-stacks them onto the outlet conveyor, then transfers them to the packing area, realizing automated downstream palletizing and packing. The palletizer has four rubber-sleeved clamping arms, is hydraulically operated, and can move 360 degrees horizontally.

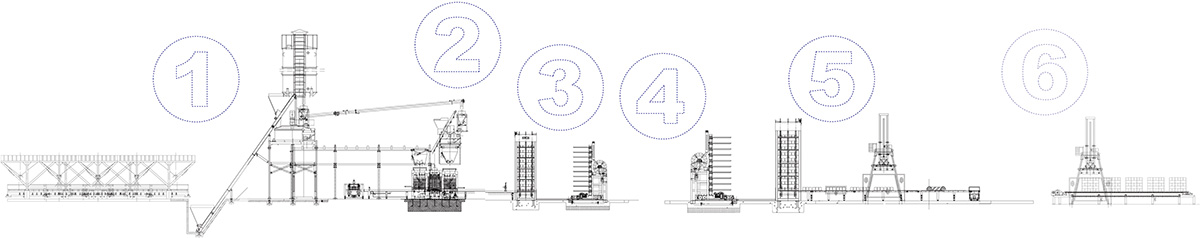

——Fully Automatic Production Line Diagram——

Marketing Center

Tel: 0595-22359222 22359333Overseas Sales

Tel: 0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com