Language

Language

——Features——

1. By changing molds, it can produce road shoulders and curbs, river channel and slope protection blocks, plaza/wharf pavers, insulation bricks, landscaping bricks, wall bricks, grass-planting pavers, etc.—one machine, multiple applications.

2. Fixed vibration table enables faster mold changes. The floating vibration system effectively extends mold service life and reduces vibration wear on the equipment.

3. Low-frequency feeding + high-frequency vibration; table–mold compaction vibration fully liquefies and degasses concrete within 2–3 seconds, suitable for producing high-strength, high-density blocks.

4. Imported electrical and hydraulic components ensure smooth operation of the control and hydraulic systems. Human–machine interface with fully automatic operation; automatic product-density analysis, automatic feed-ratio adjustment, and automatic fault diagnosis—an intelligent control system.

5. Product height range: 40–200 mm, and high, maintenance-free productivity helps customers recover their investment in a short time.

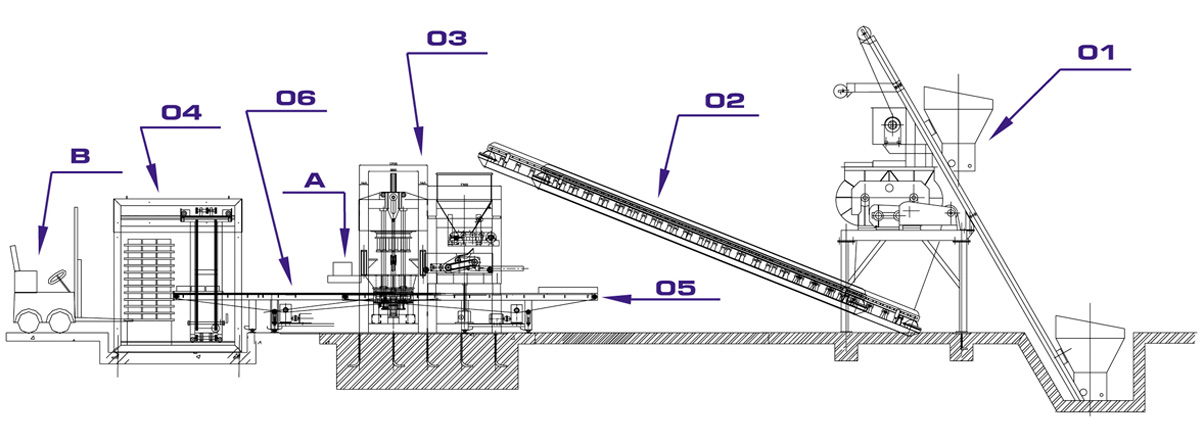

| Item | Model | Power |

| 01 Forced Mixer | JS500 | 26KW |

| 02 Belt Conveyor | 8M | 2.2KW |

| 03 QT6-15 Block Forming Machine | QT6-15 | 33.2KW |

| 04 Pallet Elevator | For QT6-15 | 3KW |

| 05 Pallet Feeder | For QT6-15 | |

| 06 Block Conveyor | For QT6-15 | 1.5KW |

| A Face-material Device (Optional) | For QT6-15 | |

| B Forklift (Optional) | 3T | |

| Brick Surface Cleaner (Optional) | For QT6-15 |

Marketing Center

Tel: 0595-22359222 22359333Overseas Sales

Tel:0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com