Language

Language

——Introduction——

Brick-making from muck soil—who else but us

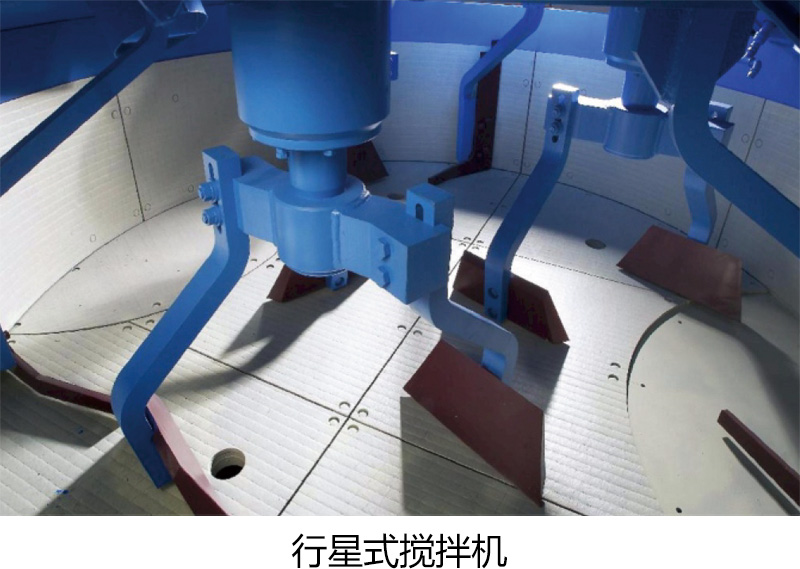

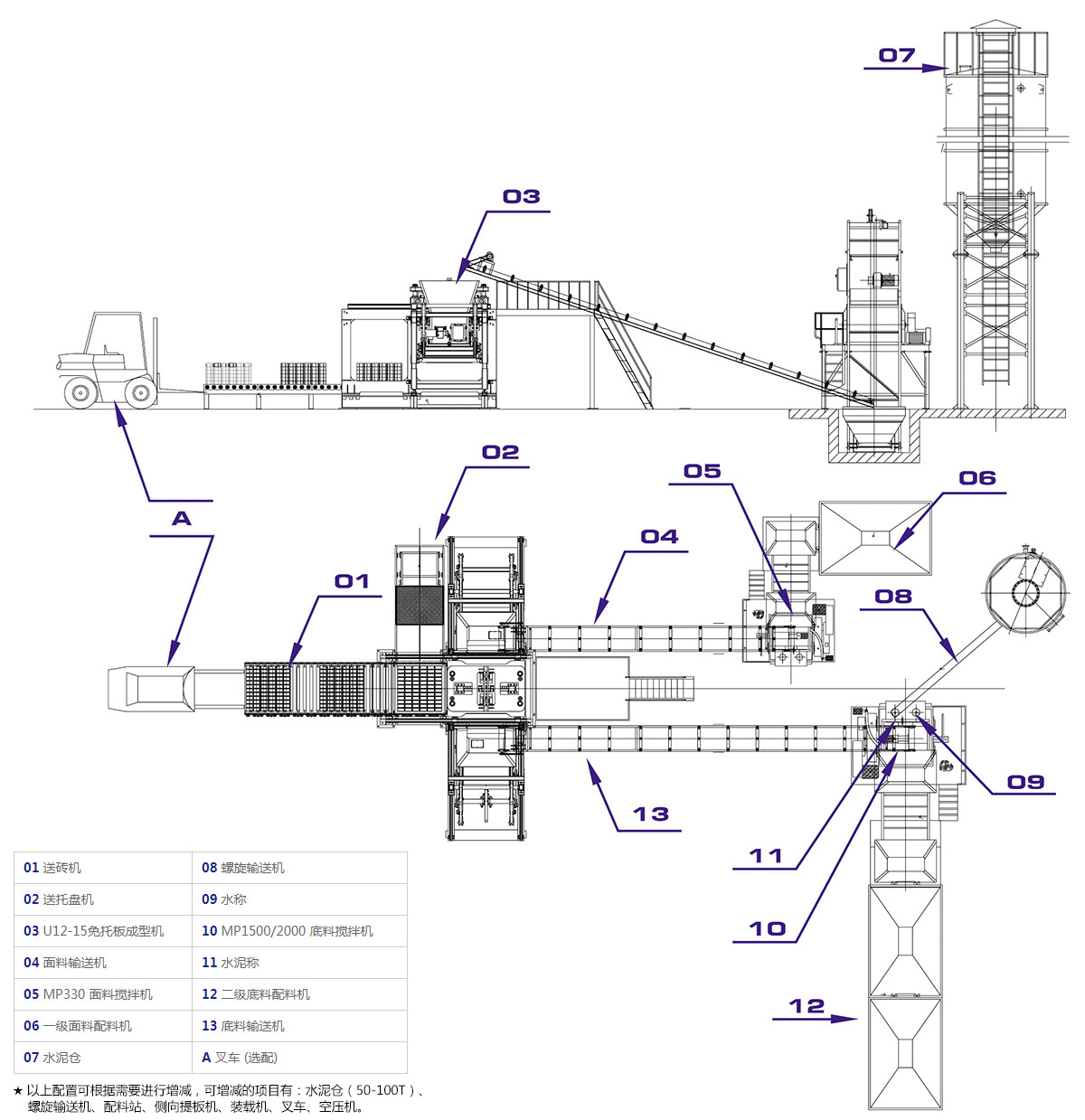

The U12-15 pallet-free fully automatic production line is a wall and floor tile forming equipment independently developed by our company! The effective production area can reach 1.08×1.08 m²; the product bulk density can reach 2400 kg/m³, and water absorption can be below 6%; product weight tolerance is only ±1.5%, and strength tolerance can reach ±10%; product height tolerance can be controlled within ±0.2 mm; automatic stacking immediately after forming, pallet-free, no auxiliary facilities, no consumables; single-shift capacity of 100,000 standard bricks; with automatic strapping only 3 workers are needed, and no manual labor is required for subsequent loading and unloading!

Immediately stacking after forming not only saves the large investment in pallets required by traditional processes, and the moving mold stripping of the forming host also saves links such as “elevator, lowering machine, product transfer, rail car, entering and exiting curing kiln”. The main machine is also a stacker, reducing many intermediate links, allowing users to reduce investment in a large amount of supporting equipment and facilities, and making maintenance easier—both cost-saving and labor-saving.

The equipment is suitable for producing high-quality, high-strength concrete or fly ash blocks. It is one of the advanced and reliable models on the domestic market. Production lines with various configurations can meet users’ processing requirements and output demands for most concrete products.

——Features——

1. Large forming area: effective forming area up to 1.08 m*1.08 m.

2. High single-machine capacity: 15~18 seconds per forming cycle; each cycle produces 12 pieces of 390*190*190 products; hourly output of standard bricks up to 13,680 pieces.

3. Pallet-free production: stack immediately after forming; no need for a large investment in hundreds of thousands of pallets.

4. High-density forming: bulk density per cubic meter up to 2.3T; water absorption can be less than 8%. High density enables high-strength products with less cement, and materials with higher clay content can also produce high-quality products.

5. Saves a lot of labor: stack immediately after forming; no need for auxiliary equipment such as finished product curing transfer and stacking.

6. Mobile modular design: the equipment is divided into several modules; quick on-site installation; production can start upon setup; no plant construction lead time; equipment can be quickly relocated with the project and market.

7. We can operate the project for users, responsible for: quality management, capacity assurance, cost control, equipment maintenance, and mix/formulation process.

Marketing Center

Tel:0595-22359222 22359333Overseas Sales

Tel:0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com