Language

Language

——Features——

1.Specific fixed pallet device prevents pallet from moving back and forth, isolated pallet device reduces pallet wear, extending pallet service life.

2.Original imported hydraulic components,to ensure product reliability and accuracy。Guide columns never need replacement,Reduce maintenance costs。

3.Adopting energy-saving vibration system, vibration force size can be arbitrarily adjusted, reducing damage to equipment and mold from vibration force. Variable frequency synchronous vibration method provides greater vibration force, higher brick density, and less cement consumption.

4. New feeding trolleyEquipped with wear-resistant and anti-leakage devices。

5. Bottom mold equipped with gear rack synchronization device,Ensure bricks are not damaged when the bottom mold is demolded。

6. Synchronous gearbox moved externally,Ensure the vibration box does not leak oil,While reducing vibration energy consumption。

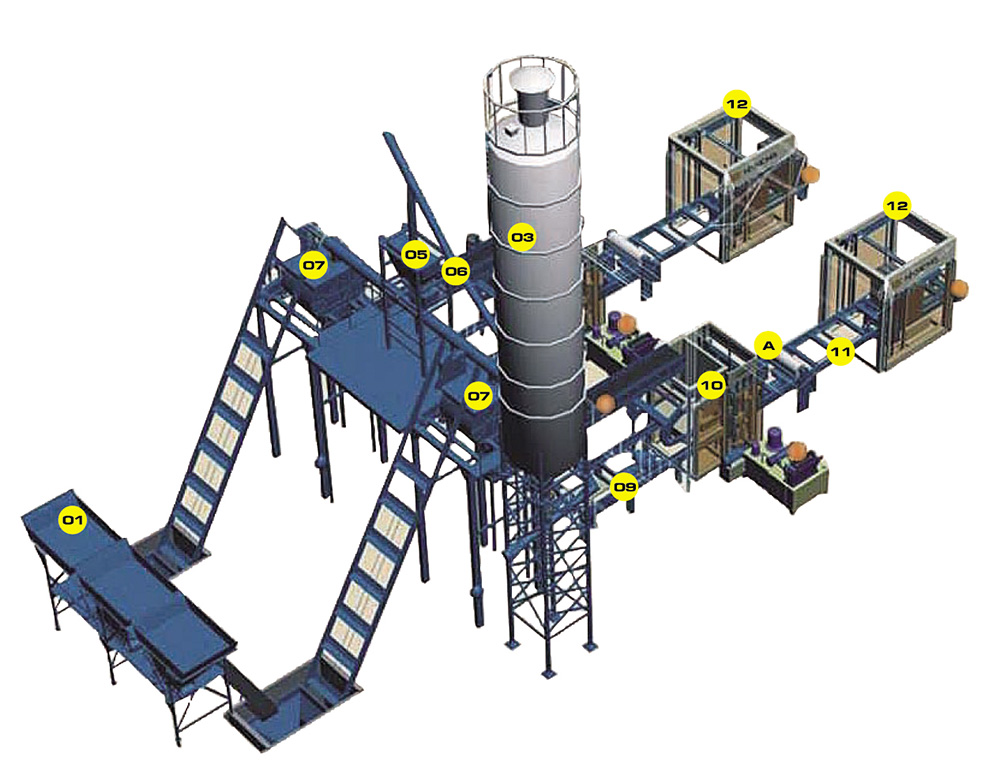

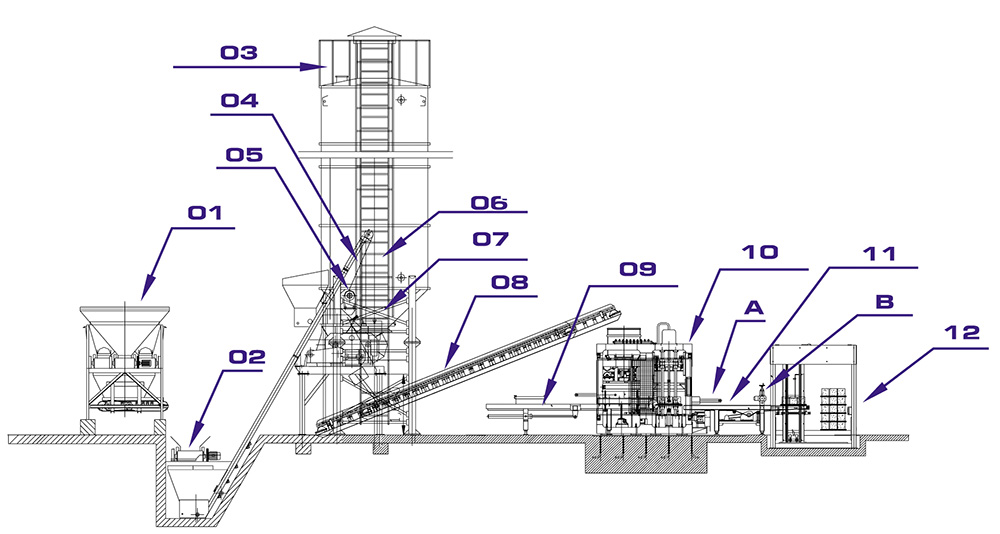

| Item | Model | Power |

| 01 3-bin Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 8M | 2.2KW |

| 03 Cement Silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7M | 7.5KW |

| 07 Forced Mixer | JS750 | 38.6KW |

| 08 Mixing Material Conveyor | 8M | 2.2KW |

| 09 Pallet Feeder | QT9-15 Supporting | 1.5KW |

| 10 QT9-15 Block Forming Machine | QT9-15 | 46.2KW |

| 11 Block Conveyor | QT9-15 Supporting | 1.5KW |

| 12 Pallet Elevator | QT9-15 Supporting | 3.7KW |

| A Face-material Device (Optional) | QT9-15 Supporting | |

| B Brick Surface Cleaner (Optional) | QT9-15 Supporting |

★The above configuration can be adjusted as needed. Optional items include: cement silo (50-100T), screw conveyor, batching station, side board lifter, loader, forklift, air compressor.

Marketing Center

Tel:0595-22359222 22359333Overseas Sales

Tel:0086-595-86531818 0086-595-86531168 0595-22359222

0595-22359222

13599204288

13599204288

sales@honcha.com

sales@honcha.com